- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

LQMX1300

UPG

| Availability: | |

|---|---|

| Quantity: | |

Feature

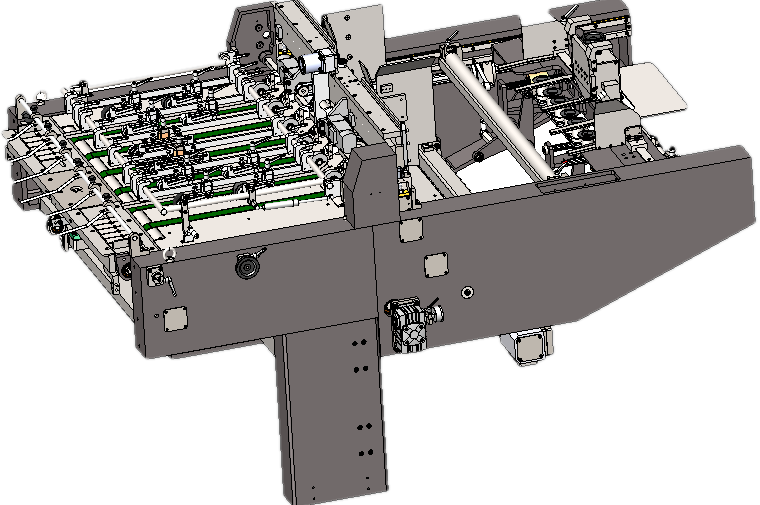

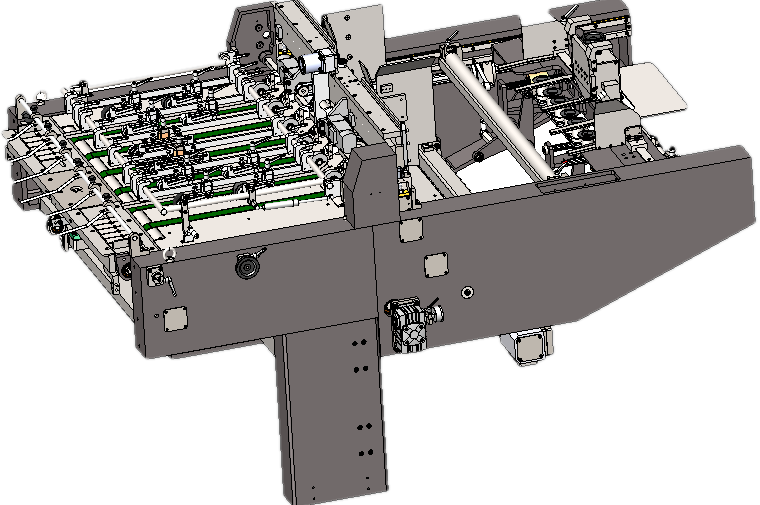

This machine is a special equipment for die-cutting of high-end color corrugated boxes, which is innovatively developed by our company, and realizes automation from paper feeding, die-cutting and paper delivery.

The unique lower sucker structure can realize continuous non-stop paper feeding and effectively avoid the scratch problem of the color boxes.

It adopts advanced mechanisms such as high-precision intermittent indexing mechanism, Italian pneumatic clutch, manual pressure regulation, and pneumatic chase locking device.

The rigorous and precise manufacturing process guarantees accurate, efficient and stable operation of the whole machine.

Detail Characteristics

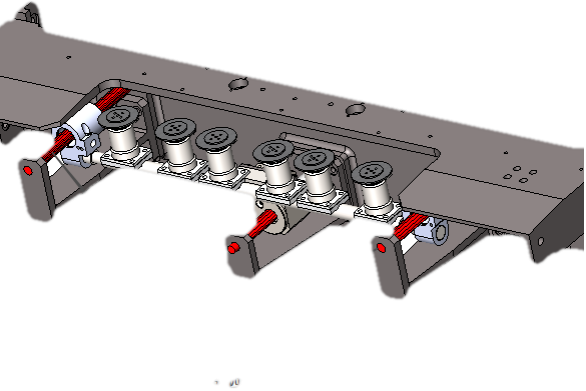

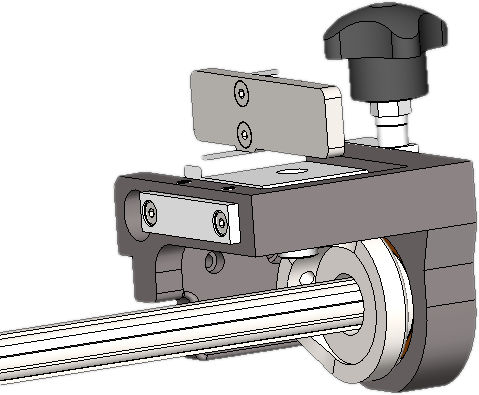

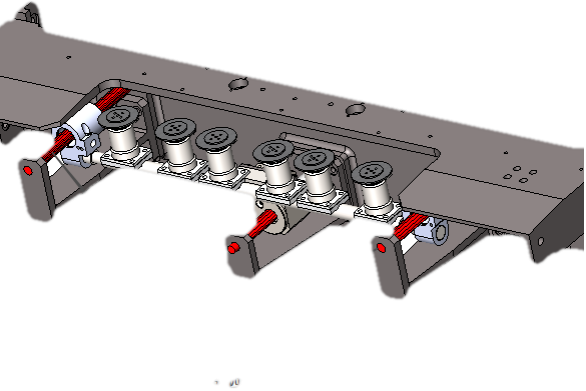

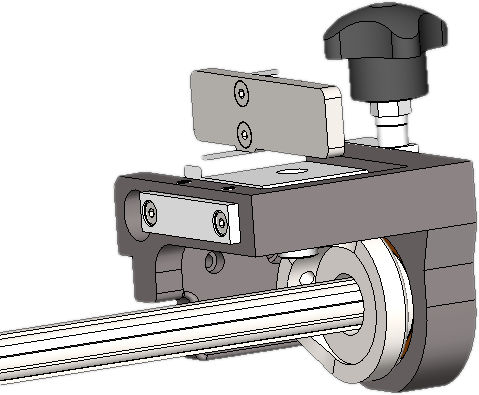

Feeding Unit

|  |  |

| The paper feeding adopts advanced lower sucker mechanism, and the main power source comes from the die-cutting part, which realizes non-stop paper feeding, stable and efficient. | The sliding parts adopt high-quality ball splines and are equipped with automatic lubrication structure to ensure the accuracy of mechanical operation and increase the service life. | The suckers can be adjusted at any time according to the bending of the paper to ensure stable operation, reduce downtime and improve work efficiency. |

|  |  |

| The unique anti- scratch structure reduces the scratch and improves the quality of die cutting. | The positioning push lays on the left and right adopts a high-precision cam structure to ensure that the paper is stable and accurate in place under high-speed work. It is driven by spline and has higher precision. | The paper feeding part is servo driven, and the paper has a speed down process before reaching the front lay to ensure that the paper is accurately positioned and the leading edge is flat |

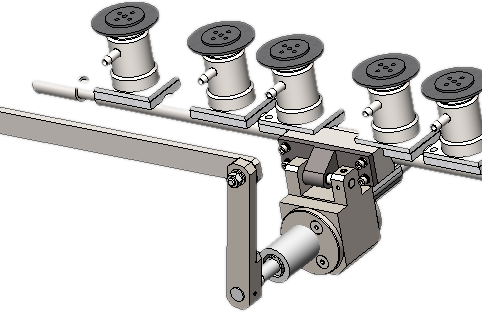

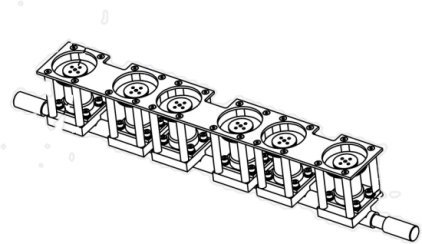

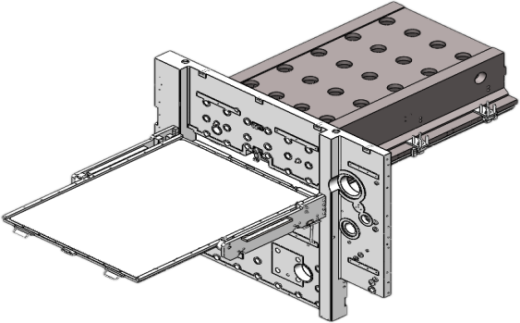

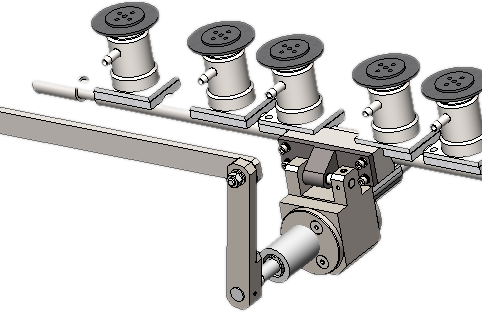

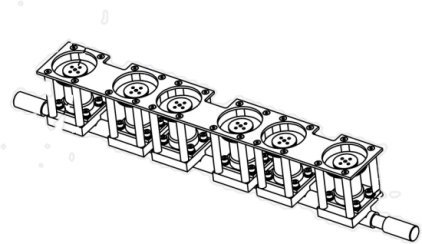

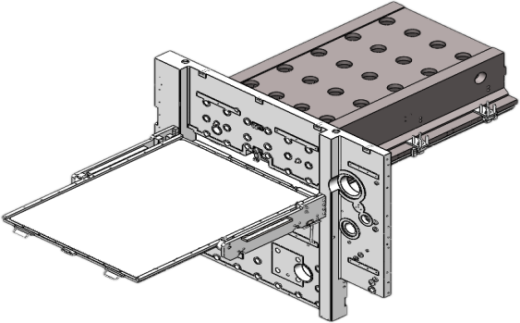

Die Cutting Unit

| ||

| It adopts precision worm gear and crankshaft connecting rod mechanism to make the mechanical transmission stable. Worm gears and crankshaft connecting rods are made of high-grade alloy materials and are precision ground and processed by large imported machining tools. The main transmission parts are assembled by senior technicians after scraping and grinding to extend the service life of the machine. | The key components such as the bottom platform,moving platform,upper upper platform, and machine body are cast from high-strength ductile iron and processed by a large-scale imported machineing center to ensure stable die-cutting pressure and save plate-ready time. | The moving platform is equipped with a compression spring to make the platform move up and down more smoothly and save the main motor. |

|  |  |

| The die-cutting chase is designed to be safe and easy to move. The rotary device makes the plate loading and adjustment faster and more convenient. The pneumatic locking makes the chase fixed firmly, accurately and time-saving.The steel plate is air-suspended and easy to move. | The Taiwan-made indexing device ensures more accurate indexing,higher die-cutting accuracy. | It adopts Italian pneumatic clutch, which has long life, low noise, stable braking, fast clutch, large transmission force, more stable and durable performance.

|

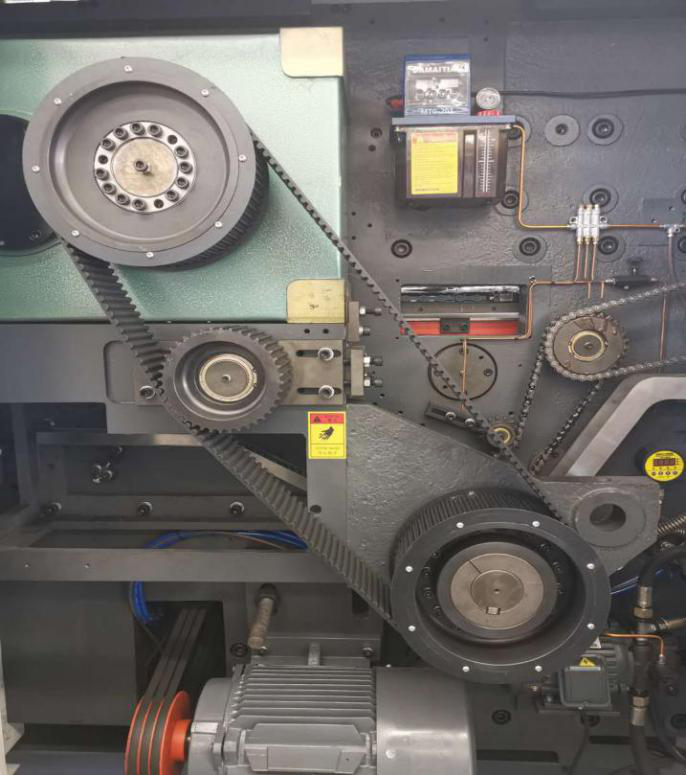

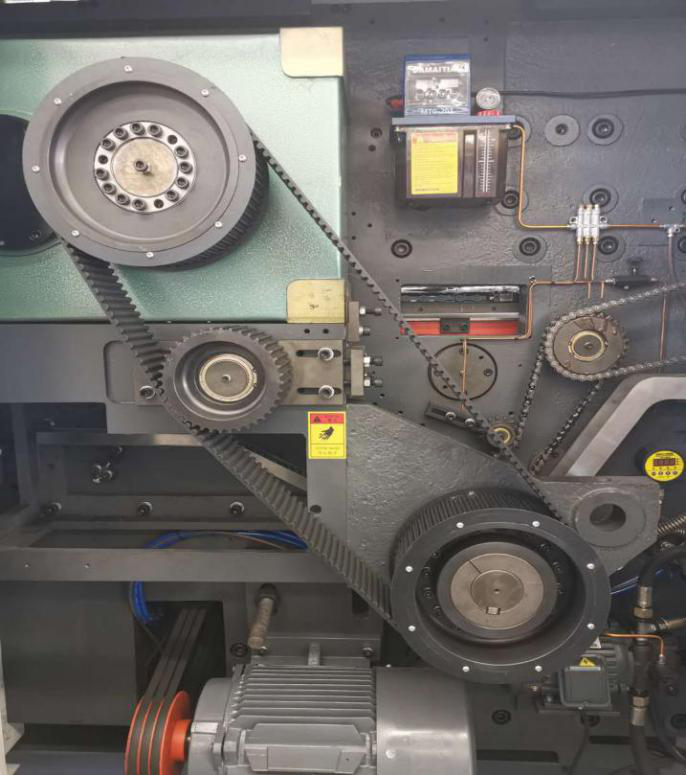

Transmission Part

| Using toothed belt for transmission, higher accuracy and better stability. |

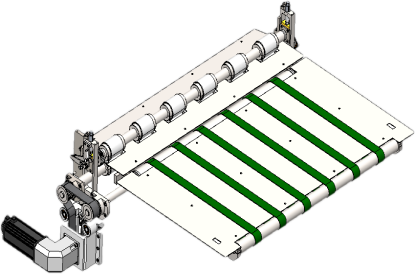

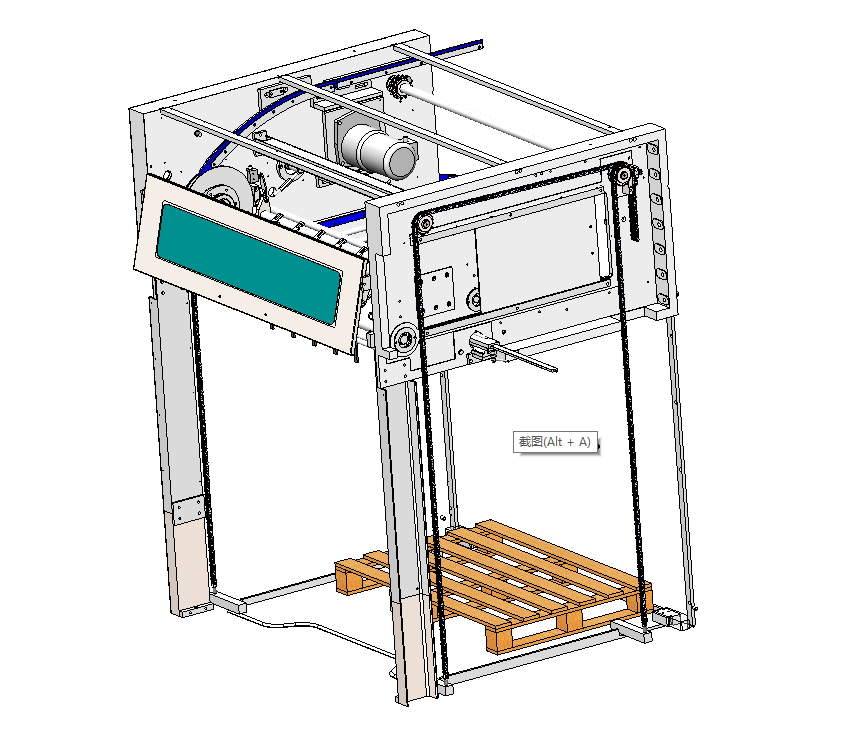

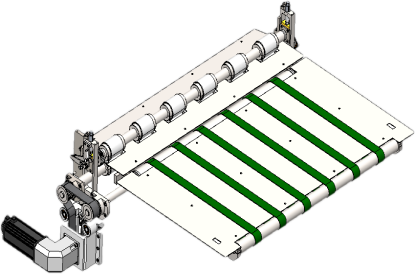

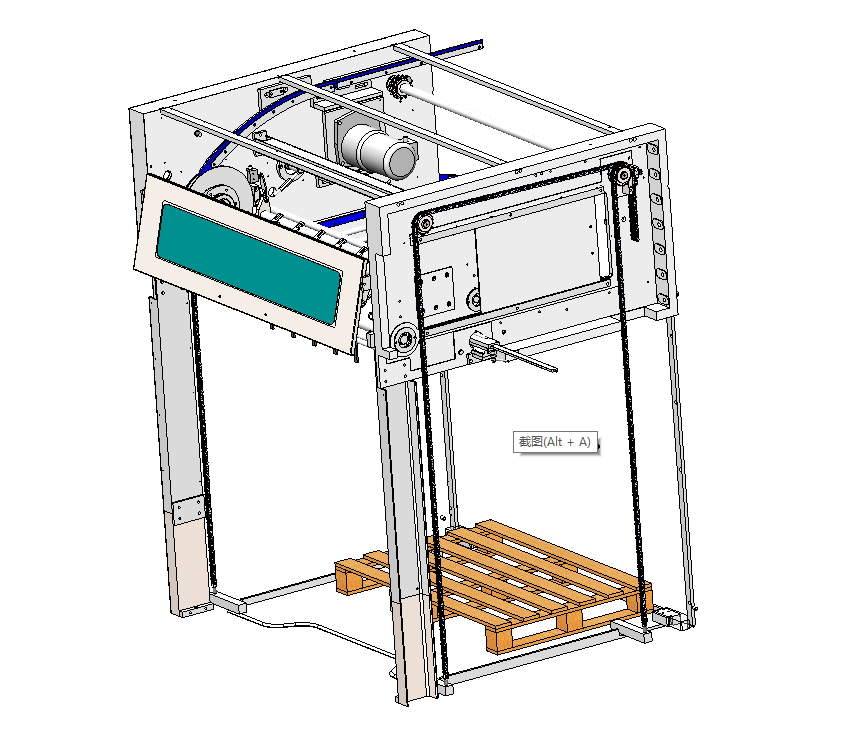

Delivery Part

|  |

| The delivery table is used for paper collection. There are detection switches in many places to ensure the paper pile automatically lowers down and alarms for speed down when paper is full to avoid ver-height. | Anti-return photoelectric switch prevents paper from rolling up. |

Lubrication part

| The automatic lubrication system enables that the lubrication time and the amount of oil can be set freely according to the actual situation. The lubrication points include the chain for gripper bar, transmission chain, cam and other relative moving parts. |

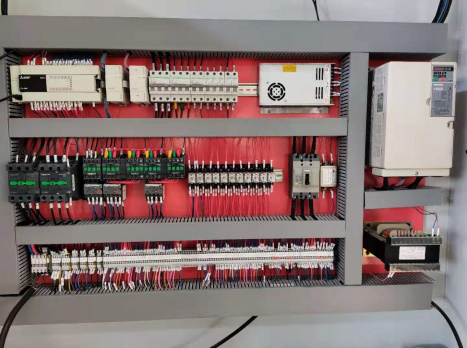

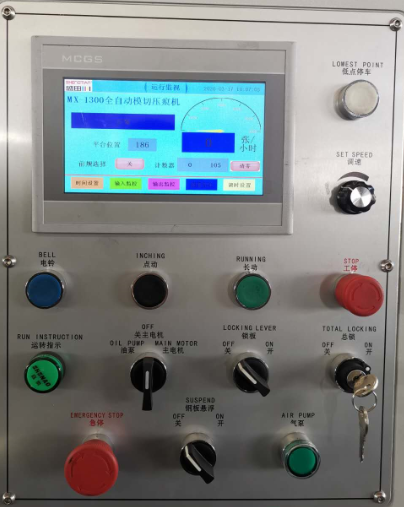

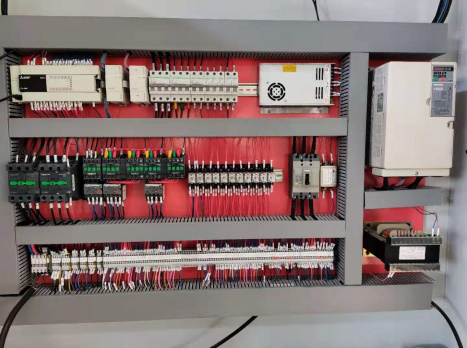

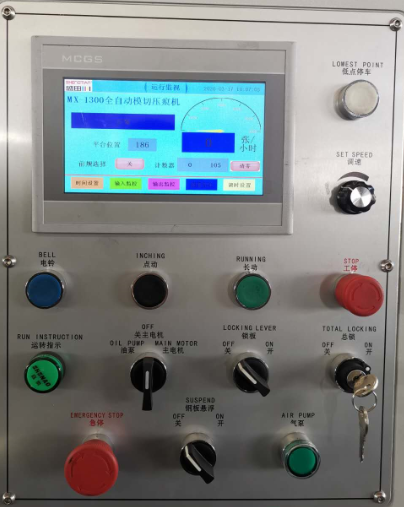

Electric Control System

|  |

| PLC controls the operation of the whole machine and the trouble monitoring system. The electrical components and monitoring switches use famous brands from Japan, Germany, France, Taiwan, etc., with precise motion control and stable performance. | Human-computer interaction is carried out by the high-resolution LCD touch screen throughout the work, which is convenient for the operator to monitor the running condition of the machine and troubleshoot in time. |

Feature

This machine is a special equipment for die-cutting of high-end color corrugated boxes, which is innovatively developed by our company, and realizes automation from paper feeding, die-cutting and paper delivery.

The unique lower sucker structure can realize continuous non-stop paper feeding and effectively avoid the scratch problem of the color boxes.

It adopts advanced mechanisms such as high-precision intermittent indexing mechanism, Italian pneumatic clutch, manual pressure regulation, and pneumatic chase locking device.

The rigorous and precise manufacturing process guarantees accurate, efficient and stable operation of the whole machine.

Detail Characteristics

Feeding Unit

|  |  |

| The paper feeding adopts advanced lower sucker mechanism, and the main power source comes from the die-cutting part, which realizes non-stop paper feeding, stable and efficient. | The sliding parts adopt high-quality ball splines and are equipped with automatic lubrication structure to ensure the accuracy of mechanical operation and increase the service life. | The suckers can be adjusted at any time according to the bending of the paper to ensure stable operation, reduce downtime and improve work efficiency. |

|  |  |

| The unique anti- scratch structure reduces the scratch and improves the quality of die cutting. | The positioning push lays on the left and right adopts a high-precision cam structure to ensure that the paper is stable and accurate in place under high-speed work. It is driven by spline and has higher precision. | The paper feeding part is servo driven, and the paper has a speed down process before reaching the front lay to ensure that the paper is accurately positioned and the leading edge is flat |

Die Cutting Unit

| ||

| It adopts precision worm gear and crankshaft connecting rod mechanism to make the mechanical transmission stable. Worm gears and crankshaft connecting rods are made of high-grade alloy materials and are precision ground and processed by large imported machining tools. The main transmission parts are assembled by senior technicians after scraping and grinding to extend the service life of the machine. | The key components such as the bottom platform,moving platform,upper upper platform, and machine body are cast from high-strength ductile iron and processed by a large-scale imported machineing center to ensure stable die-cutting pressure and save plate-ready time. | The moving platform is equipped with a compression spring to make the platform move up and down more smoothly and save the main motor. |

|  |  |

| The die-cutting chase is designed to be safe and easy to move. The rotary device makes the plate loading and adjustment faster and more convenient. The pneumatic locking makes the chase fixed firmly, accurately and time-saving.The steel plate is air-suspended and easy to move. | The Taiwan-made indexing device ensures more accurate indexing,higher die-cutting accuracy. | It adopts Italian pneumatic clutch, which has long life, low noise, stable braking, fast clutch, large transmission force, more stable and durable performance.

|

Transmission Part

| Using toothed belt for transmission, higher accuracy and better stability. |

Delivery Part

|  |

| The delivery table is used for paper collection. There are detection switches in many places to ensure the paper pile automatically lowers down and alarms for speed down when paper is full to avoid ver-height. | Anti-return photoelectric switch prevents paper from rolling up. |

Lubrication part

| The automatic lubrication system enables that the lubrication time and the amount of oil can be set freely according to the actual situation. The lubrication points include the chain for gripper bar, transmission chain, cam and other relative moving parts. |

Electric Control System

|  |

| PLC controls the operation of the whole machine and the trouble monitoring system. The electrical components and monitoring switches use famous brands from Japan, Germany, France, Taiwan, etc., with precise motion control and stable performance. | Human-computer interaction is carried out by the high-resolution LCD touch screen throughout the work, which is convenient for the operator to monitor the running condition of the machine and troubleshoot in time. |

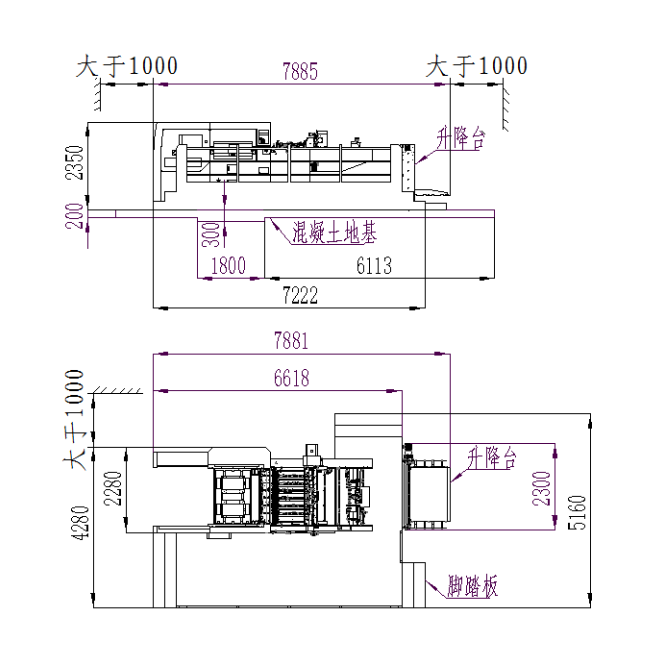

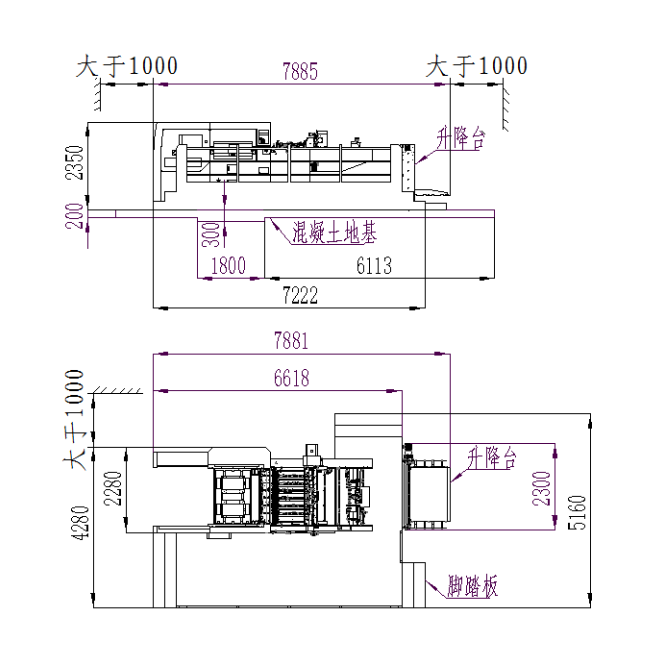

Model | LQMX 1300 |

Max.paper size | 1320×960mm |

Min.paper size | 450×420mm |

Max.die-cutting size | 1300×950mm |

Inner size of the chase | 1320×946mm |

Thickness of the paper | ≤8(Corrugated board)mm |

Gripper margin | 9-17mm,standard13mm |

Max. working pressure | 300T |

Max. speed | 6000sheets/h |

Total power | 26KW |

Air source pressure/Air flow | 0.55-0.7MPa/>0.6m³/min |

Weight | 1600kg/1500kg |

Overall dimensions (L×W×H) | 7820×5420×2370mm |

Machine weight | 18t |

Configuration

No. | Name | Location | Brand | No. | Name | Location | Brand |

1 | Worm gear | Main drive | With manual scraping | 11 | Bearing in key parts | All | UBC、IKO |

2 | Cranshaft | Main drive | Tempering, high frequency quenching | 12 | Servo drive | Die-cutting | Yaskawa, Japan |

3 | Worm | Main drive | Tempering, high frequency quenching | 13 | Touch screen | Main control | Weinview, Taiwan |

4 | Vacuum pump | Feeding | Tongyou, China | 14 | Inverter | Main control | Toshiba, Japan |

5 | Indexing device | Taiwan | 15 | Stabilized voltage supply | Main control | Meanwell, Taiwan | |

6 | Pneumatic clutch | Ompi, Italy | 16 | PLC | Main control | Mitsubishi, Japan | |

7 | Reducer | Delivery | CBG.Taiwan | 17 | Air switch | Main control | Schneider |

8 | Reducer | Lifting | CBG.Taiwan | 18 | Breaker/ contactor | Main control | Schneider |

9 | Th | Die-cutting | Siemens | 19 | Contactor | Main control | Schneider |

10 | Servo motor | Feeding | Inovance | 20 | Intermediate relay | Main control | Idec,Japan |

Model | LQMX 1300 |

Max.paper size | 1320×960mm |

Min.paper size | 450×420mm |

Max.die-cutting size | 1300×950mm |

Inner size of the chase | 1320×946mm |

Thickness of the paper | ≤8(Corrugated board)mm |

Gripper margin | 9-17mm,standard13mm |

Max. working pressure | 300T |

Max. speed | 6000sheets/h |

Total power | 26KW |

Air source pressure/Air flow | 0.55-0.7MPa/>0.6m³/min |

Weight | 1600kg/1500kg |

Overall dimensions (L×W×H) | 7820×5420×2370mm |

Machine weight | 18t |

Configuration

No. | Name | Location | Brand | No. | Name | Location | Brand |

1 | Worm gear | Main drive | With manual scraping | 11 | Bearing in key parts | All | UBC、IKO |

2 | Cranshaft | Main drive | Tempering, high frequency quenching | 12 | Servo drive | Die-cutting | Yaskawa, Japan |

3 | Worm | Main drive | Tempering, high frequency quenching | 13 | Touch screen | Main control | Weinview, Taiwan |

4 | Vacuum pump | Feeding | Tongyou, China | 14 | Inverter | Main control | Toshiba, Japan |

5 | Indexing device | Taiwan | 15 | Stabilized voltage supply | Main control | Meanwell, Taiwan | |

6 | Pneumatic clutch | Ompi, Italy | 16 | PLC | Main control | Mitsubishi, Japan | |

7 | Reducer | Delivery | CBG.Taiwan | 17 | Air switch | Main control | Schneider |

8 | Reducer | Lifting | CBG.Taiwan | 18 | Breaker/ contactor | Main control | Schneider |

9 | Th | Die-cutting | Siemens | 19 | Contactor | Main control | Schneider |

10 | Servo motor | Feeding | Inovance | 20 | Intermediate relay | Main control | Idec,Japan |

ADD: ROOM 2403 JINCHENG MANSION 511

TIANMUXI ROAD, SHANGHAI, 200070,P.R. CHIN

TEL: +86-021-63173900-101 +86-021-63173900

E-MAIL: huangwei@shanghai-upg.com