- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

PVC based board

Product flexibility,easy to repair

Usually used in paper jam and corrugated die-cutting indentation

Die-cutting indentation about 30000~40000 times

The most complete specifications,good stability,cost-effective commonly used creasing matrix

Scope of application

These creasing matrix are suitable for short and medium board products such as paper jam,corrugated packing box and so on.

Standard

Available for 0.6~6mm channel

each pcs length is 70cm,packed in 50pcs/box

13mm base

Off centre

Enabling two creases very close together

Ultra-narrow

Available for 0.6~6mm channel

each pcs length is 70cm,packed in 50pcs/box

9mm base

Double Crease

For job requiring 2 creases close together,special locator fits both creasing rules.

-------------------------------------------------------------------------------------------------------------------------------

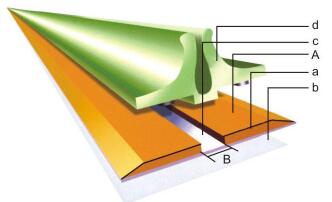

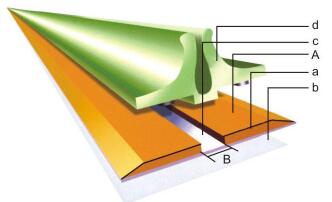

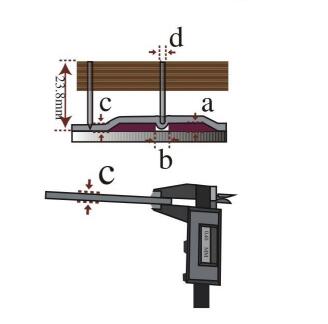

Structure of creasing matrix

a. Creasing Matrix Base Board

b. Open protective adhesive tape paper

c. Strong bottom film

d. Creasing Matrix Positing Strip

A. Creasing Matrix Thickness

B. Creasing Matrix Groove Width

The instruction of Creasing matrix

1. First Measure the creasing rule length of the die making boarding.

2. Cut the creasing matrix according to the measuring length,and cut the two ends naturally into 90 degrees sharp angle.

3. Fix the elastic opening of the positioning strip of the creasing matrix to the creasing rules.

4.After the creasing matrix is all clamped,tear off the bottom protective adhesive tape.

5. The die-cutting machine will be installed to start the die-cutting machine once,the creasing matrix is located on the bottom die plate.

6.Tear off the creasing matrix positioning strip,creasing matrix indentation die positioning completed.

How to choose the correct creasing matrix style?

In the process of die-cutting,different types of paper should choose different specifications of creasing matrix,which Paper jam and corrugated cardboard have different selection methods.

Comparison Table for Paper Jam Selection

Paper gram | Paper thickness | Steel creasing rule height | chosen creasing matrix style 0.71mm creasing rule thickness | chosen creasing matrix style 1.05mm creasing rule thickness |

150.00 | 0.21 | 23.60 | 0.2*0.8 | - |

200.00 | 0.28 | 23.50 | 0.3*1.0 | - |

230.00 | 0.32 | 23.50 | 0.3*1.2 | - |

250.00 | 0.35 | 23.50 | 0.3*1.3 | - |

300.00 | 0.42 | 23.40 | 0.4*1.3 | - |

350.00 | 0.50 | 23.30 | 0.5*1.5 | - |

400.00 | 0.56 | 23.30 | 0.5*1.6 | - |

450.00 | 0.63 | 23.20 | 0.5*1.6 | - |

500.00 | 0.70 | 23.10 | 0.6*1.7 | 0.6*1.9 |

500.00 | 0.70 | 23.10 | 0.7*1.7 | 0.7*2.1 |

550.00 | 0.77 | 23.00 | 0.8*1.9 | 0.8*2.3 |

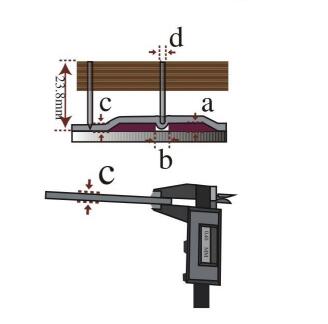

a=creasing matrix thickness

a=creasing matrix thickness

b=groove width of the creasing matrix

c=paper jam thickness

d=creasing rule thickness

e=the flatten corrugated cardboard thickness

a=c b=(c×2)+d

First,measure the thickness of the paper jam with a caliper.The thickness of the creasing rule selected for die-cutting should be greater than or equal to the thickness of the paper,and the groove depth of the creasing matrix should be equal to the thickness of the paper.

In production practice,the groove width of the creasing matrix can be selected according to the following formula:

*creasing matrix groove width = paper jam thickness×1.5+creasing rule thickness.

How to choose the correct creasing matrix style?

Comparison Table for corrugated cardboard Selection

Corrugated Cardboard | the flatten corrugated cardboard thickness | the creasing rule height | chosen creasing matrix style 1.05mm creasing rule thickness | chosen creasing matrix style 1.42mm creasing rule thickness |

E pit | 0.65 | 23.10 | 0.7*2.3 | - |

E pit | 0.75 | 23.00 | 0.8*2.5 | - |

B pit | 0.85 | 22.90 | 0.8*2.7 | 0.8-3.2 |

B pit | 0.95 | 22.80 | 1.0-3.0 | 1.0*3.5 |

C pit | 1.05 | 22.70 | 1.0*3.2 | 1.0*3.5 |

C pit | 1.15 | 22.60 | - | 1.0*4.0 |

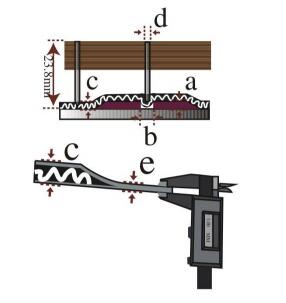

a=creasing matrix thickness

b=groove width of the creasing matrix

c=corrugated cardboard thickness

d=creasing rule thickness

e=the flatten corrugated cardboard thickness

a=c b=(c×2)+d

First,measure the thickness of the flatten corrugated cardboard with caliper.Choose the thickness of the creasing rule is greater than or equal to the thickness of the flattening corrugated cardboard. The groove depth of the creasing matrix(the thickness of the creasing matrix) should be equal to the thickness of the flatten corrugated cardboard.

In production practice,the groove width of the creasing matrix can be selected according to the following formula:

*creasing matrix groove width = the flatten corrugated cardboard thickness×2+creasing rule thickness.

PVC based board

Product flexibility,easy to repair

Usually used in paper jam and corrugated die-cutting indentation

Die-cutting indentation about 30000~40000 times

The most complete specifications,good stability,cost-effective commonly used creasing matrix

Scope of application

These creasing matrix are suitable for short and medium board products such as paper jam,corrugated packing box and so on.

Standard

Available for 0.6~6mm channel

each pcs length is 70cm,packed in 50pcs/box

13mm base

Off centre

Enabling two creases very close together

Ultra-narrow

Available for 0.6~6mm channel

each pcs length is 70cm,packed in 50pcs/box

9mm base

Double Crease

For job requiring 2 creases close together,special locator fits both creasing rules.

-------------------------------------------------------------------------------------------------------------------------------

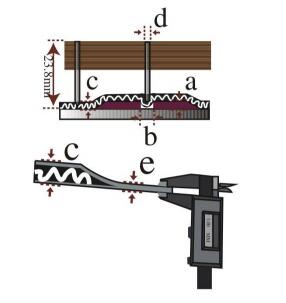

Structure of creasing matrix

a. Creasing Matrix Base Board

b. Open protective adhesive tape paper

c. Strong bottom film

d. Creasing Matrix Positing Strip

A. Creasing Matrix Thickness

B. Creasing Matrix Groove Width

The instruction of Creasing matrix

1. First Measure the creasing rule length of the die making boarding.

2. Cut the creasing matrix according to the measuring length,and cut the two ends naturally into 90 degrees sharp angle.

3. Fix the elastic opening of the positioning strip of the creasing matrix to the creasing rules.

4.After the creasing matrix is all clamped,tear off the bottom protective adhesive tape.

5. The die-cutting machine will be installed to start the die-cutting machine once,the creasing matrix is located on the bottom die plate.

6.Tear off the creasing matrix positioning strip,creasing matrix indentation die positioning completed.

How to choose the correct creasing matrix style?

In the process of die-cutting,different types of paper should choose different specifications of creasing matrix,which Paper jam and corrugated cardboard have different selection methods.

Comparison Table for Paper Jam Selection

Paper gram | Paper thickness | Steel creasing rule height | chosen creasing matrix style 0.71mm creasing rule thickness | chosen creasing matrix style 1.05mm creasing rule thickness |

150.00 | 0.21 | 23.60 | 0.2*0.8 | - |

200.00 | 0.28 | 23.50 | 0.3*1.0 | - |

230.00 | 0.32 | 23.50 | 0.3*1.2 | - |

250.00 | 0.35 | 23.50 | 0.3*1.3 | - |

300.00 | 0.42 | 23.40 | 0.4*1.3 | - |

350.00 | 0.50 | 23.30 | 0.5*1.5 | - |

400.00 | 0.56 | 23.30 | 0.5*1.6 | - |

450.00 | 0.63 | 23.20 | 0.5*1.6 | - |

500.00 | 0.70 | 23.10 | 0.6*1.7 | 0.6*1.9 |

500.00 | 0.70 | 23.10 | 0.7*1.7 | 0.7*2.1 |

550.00 | 0.77 | 23.00 | 0.8*1.9 | 0.8*2.3 |

a=creasing matrix thickness

a=creasing matrix thickness

b=groove width of the creasing matrix

c=paper jam thickness

d=creasing rule thickness

e=the flatten corrugated cardboard thickness

a=c b=(c×2)+d

First,measure the thickness of the paper jam with a caliper.The thickness of the creasing rule selected for die-cutting should be greater than or equal to the thickness of the paper,and the groove depth of the creasing matrix should be equal to the thickness of the paper.

In production practice,the groove width of the creasing matrix can be selected according to the following formula:

*creasing matrix groove width = paper jam thickness×1.5+creasing rule thickness.

How to choose the correct creasing matrix style?

Comparison Table for corrugated cardboard Selection

Corrugated Cardboard | the flatten corrugated cardboard thickness | the creasing rule height | chosen creasing matrix style 1.05mm creasing rule thickness | chosen creasing matrix style 1.42mm creasing rule thickness |

E pit | 0.65 | 23.10 | 0.7*2.3 | - |

E pit | 0.75 | 23.00 | 0.8*2.5 | - |

B pit | 0.85 | 22.90 | 0.8*2.7 | 0.8-3.2 |

B pit | 0.95 | 22.80 | 1.0-3.0 | 1.0*3.5 |

C pit | 1.05 | 22.70 | 1.0*3.2 | 1.0*3.5 |

C pit | 1.15 | 22.60 | - | 1.0*4.0 |

a=creasing matrix thickness

b=groove width of the creasing matrix

c=corrugated cardboard thickness

d=creasing rule thickness

e=the flatten corrugated cardboard thickness

a=c b=(c×2)+d

First,measure the thickness of the flatten corrugated cardboard with caliper.Choose the thickness of the creasing rule is greater than or equal to the thickness of the flattening corrugated cardboard. The groove depth of the creasing matrix(the thickness of the creasing matrix) should be equal to the thickness of the flatten corrugated cardboard.

In production practice,the groove width of the creasing matrix can be selected according to the following formula:

*creasing matrix groove width = the flatten corrugated cardboard thickness×2+creasing rule thickness.

H×W(mm) | H×W(mm) | H×W(mm) | H×W(mm) | H×W(mm) | H×W(mm) | H×W(mm) | H×W(mm) | H×W(mm) |

0.3×0.8 | 0.4×0.8 | 0.5×1.0 | 0.6×1.0 | 0.7×1.5 | 0.8×1.7 | 1.0×2.3 | 1.2×3.0 | 1.4×4.0 |

0.3×1.0 | 0.4×1.0 | 0.5×1.2 | 0.6×1.2 | 0.7×1.7 | 0.8×1.9 | 1.0×2.5 | 1.2×3.2 | 1.4×4.5 |

0.3×1.2 | 0.4×1.2 | 0.5×1.3 | 0.6×1.3 | 0.7×1.9 | 0.8×2.1 | 1.0×2.7 | 1.2×3.5 | 1.4×5.0 |

0.3×1.3 | 0.4×1.3 | 0.5×1.4 | 0.6×1.4 | 0.7×2.1 | 0.8×2.3 | 1.0×3.0 | 1.2×4.0 | 1.4×6.0 |

0.3×1.4 | 0.4×1.4 | 0.5×1.5 | 0.6×1.5 | 0.7×2.3 | 0.8×2.4 | 1.0×3.2 | 1.2×4.5 | 1.4×7.0 |

0.3×1.5 | 0.4×1.5 | 0.5×1.6 | 0.6×1.6 | 0.7×2.5 | 0.8×2.5 | 1.0×3.5 | 1.2×5.0 | |

0.4×1.6 | 0.5×1.7 | 0.6×1.7 | 0.7×2.7 | 0.8×2.7 | 1.0×4.0 | 1.2×6.0 | ||

0.4×1.7 | 0.5×1.9 | 0.6×1.9 | 0.7×2.8 | 0.8×3.0 | 1.0×4.5 | |||

0.4×1.9 | 0.5×2.1 | 0.6×2.1 | 0.7×3.0 | 0.8×3.2 | 1.0×5.0 | |||

0.5×2.5 | 0.6×2.3 | 0.7×3.2 | 0.8×3.5 | 1.0×6.0 | ||||

0.5×2.7 | 0.6×2.5 | 0.7×3.5 | 0.8×4.0 | |||||

0.6×2.7 | 0.7×4.0 | 0.8×4.5 | ||||||

0.6×3.0 | 0.8×5.0 | |||||||

0.6×3.2 | 0.8×6.0 | |||||||

0.6×3.5 | ||||||||

0.6×4.0 | ||||||||

0.6×5.0 |

*Note:the total width of the narrow base style is 9mm or 10mm,the total width of the standard base style is 13mm,and the total width of the wide base style is 15mm.

H×W(mm) | H×W(mm) | H×W(mm) | H×W(mm) | H×W(mm) | H×W(mm) | H×W(mm) | H×W(mm) | H×W(mm) |

0.3×0.8 | 0.4×0.8 | 0.5×1.0 | 0.6×1.0 | 0.7×1.5 | 0.8×1.7 | 1.0×2.3 | 1.2×3.0 | 1.4×4.0 |

0.3×1.0 | 0.4×1.0 | 0.5×1.2 | 0.6×1.2 | 0.7×1.7 | 0.8×1.9 | 1.0×2.5 | 1.2×3.2 | 1.4×4.5 |

0.3×1.2 | 0.4×1.2 | 0.5×1.3 | 0.6×1.3 | 0.7×1.9 | 0.8×2.1 | 1.0×2.7 | 1.2×3.5 | 1.4×5.0 |

0.3×1.3 | 0.4×1.3 | 0.5×1.4 | 0.6×1.4 | 0.7×2.1 | 0.8×2.3 | 1.0×3.0 | 1.2×4.0 | 1.4×6.0 |

0.3×1.4 | 0.4×1.4 | 0.5×1.5 | 0.6×1.5 | 0.7×2.3 | 0.8×2.4 | 1.0×3.2 | 1.2×4.5 | 1.4×7.0 |

0.3×1.5 | 0.4×1.5 | 0.5×1.6 | 0.6×1.6 | 0.7×2.5 | 0.8×2.5 | 1.0×3.5 | 1.2×5.0 | |

0.4×1.6 | 0.5×1.7 | 0.6×1.7 | 0.7×2.7 | 0.8×2.7 | 1.0×4.0 | 1.2×6.0 | ||

0.4×1.7 | 0.5×1.9 | 0.6×1.9 | 0.7×2.8 | 0.8×3.0 | 1.0×4.5 | |||

0.4×1.9 | 0.5×2.1 | 0.6×2.1 | 0.7×3.0 | 0.8×3.2 | 1.0×5.0 | |||

0.5×2.5 | 0.6×2.3 | 0.7×3.2 | 0.8×3.5 | 1.0×6.0 | ||||

0.5×2.7 | 0.6×2.5 | 0.7×3.5 | 0.8×4.0 | |||||

0.6×2.7 | 0.7×4.0 | 0.8×4.5 | ||||||

0.6×3.0 | 0.8×5.0 | |||||||

0.6×3.2 | 0.8×6.0 | |||||||

0.6×3.5 | ||||||||

0.6×4.0 | ||||||||

0.6×5.0 |

*Note:the total width of the narrow base style is 9mm or 10mm,the total width of the standard base style is 13mm,and the total width of the wide base style is 15mm.

ADD: ROOM 2403 JINCHENG MANSION 511

TIANMUXI ROAD, SHANGHAI, 200070,P.R. CHIN

TEL: +86-021-63173900-101 +86-021-63173900

E-MAIL: huangwei@shanghai-upg.com